Remote Working For Improved Sustainability

Greta Thunberg and other environmental activists quite rightly make the important point that humanity is following an unsustainable path in terms of using the planet’s resources and polluting the atmosphere that we all need to live in. That had been playing on our minds for some time, given the amount of travelling which we were undertaking to support our projects around the world.

Our golf course design practice had evolved to cover places as far afield as Canada, Peru, Chile and Japan, as well as numerous countries in the European region. How could we cut our carbon footprint, which had risen larger over the years as the business had grown, without compromising the final results of the construction work?

We conceived a few thoughts and ideas and had begun to consider how we might bring them into practice. Then Covid-19 came along, and we were locked down. How could we continue to serve our projects and maintain our standards? This was brought into focus with major projects getting started overseas in 2020.

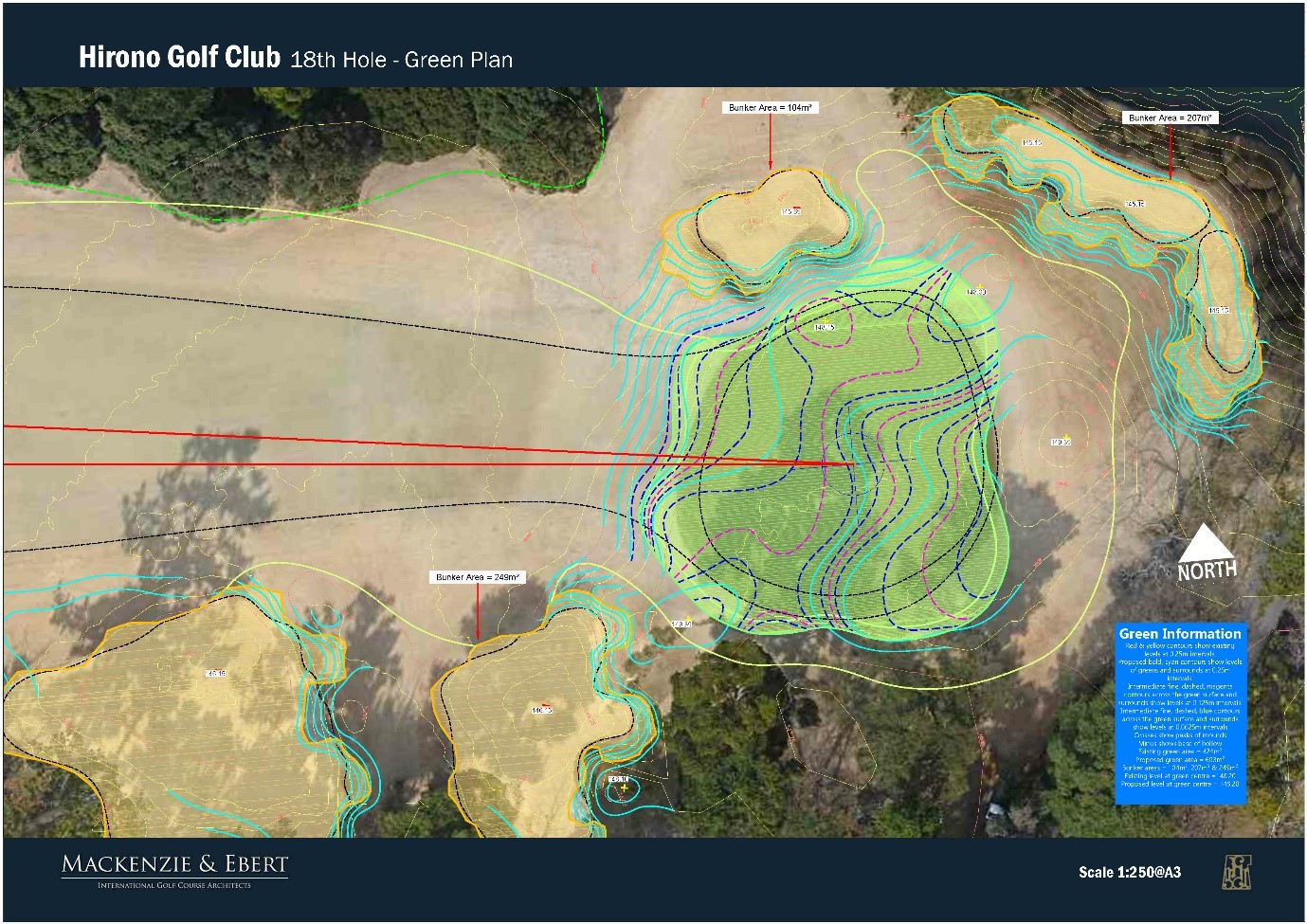

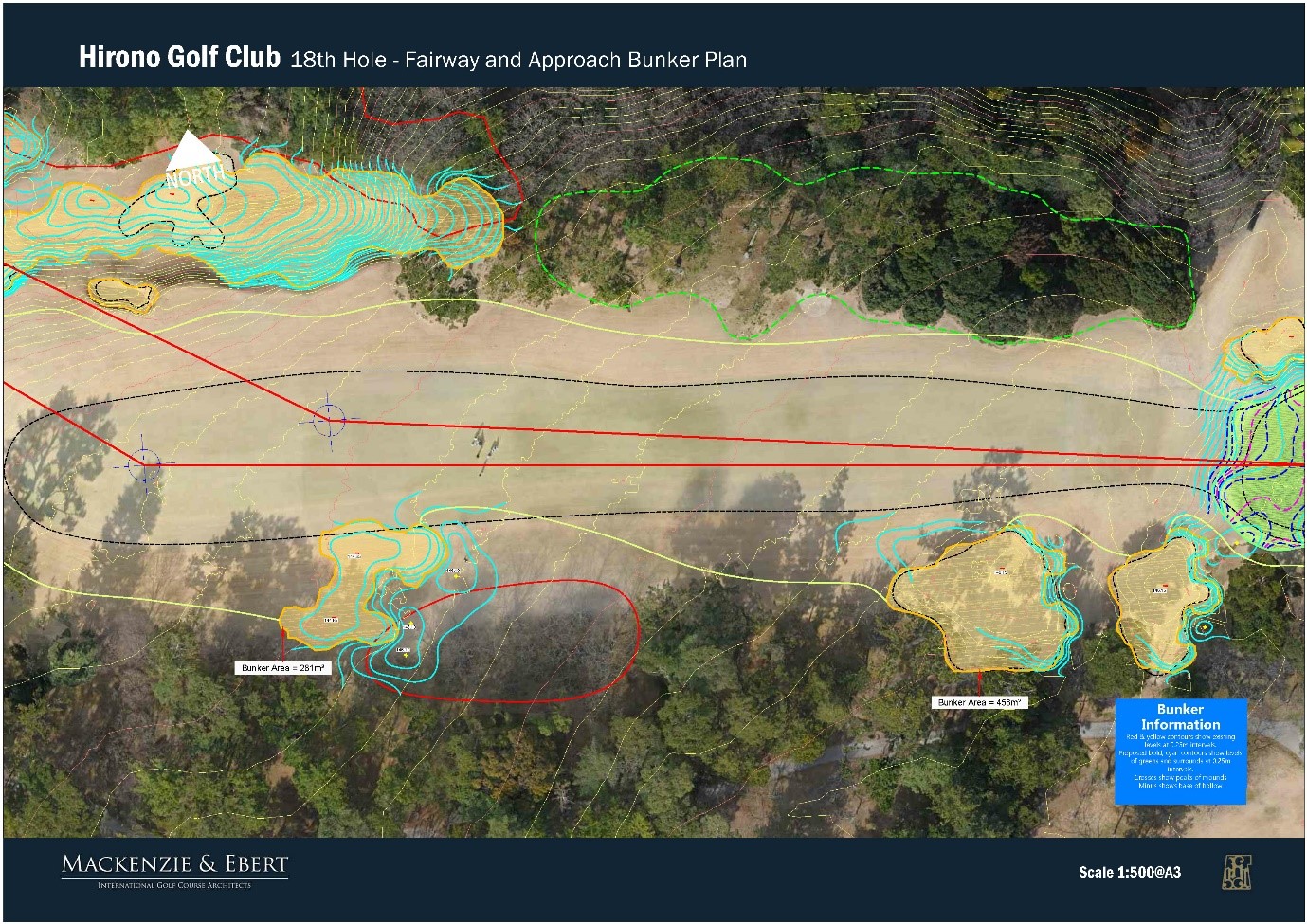

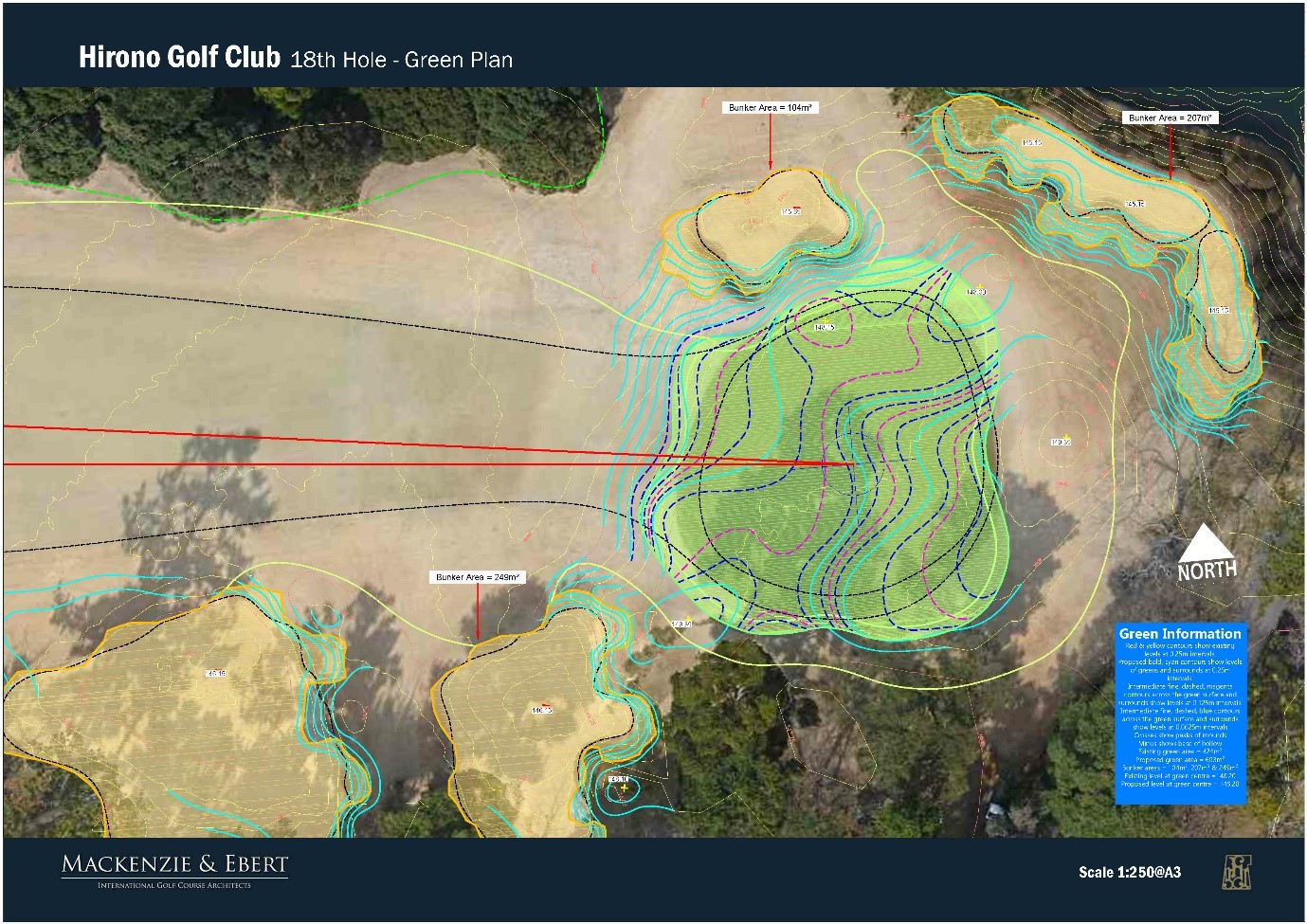

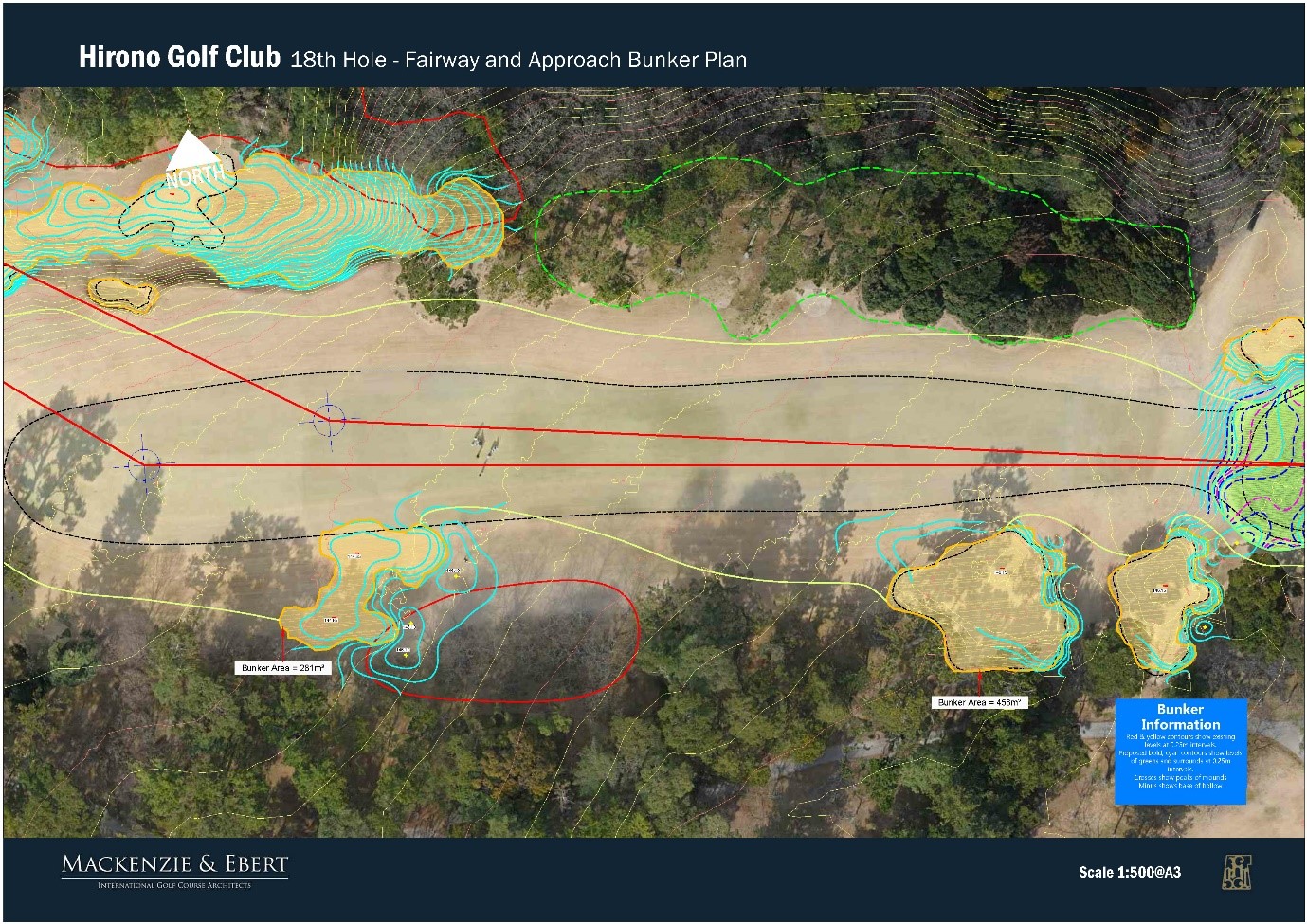

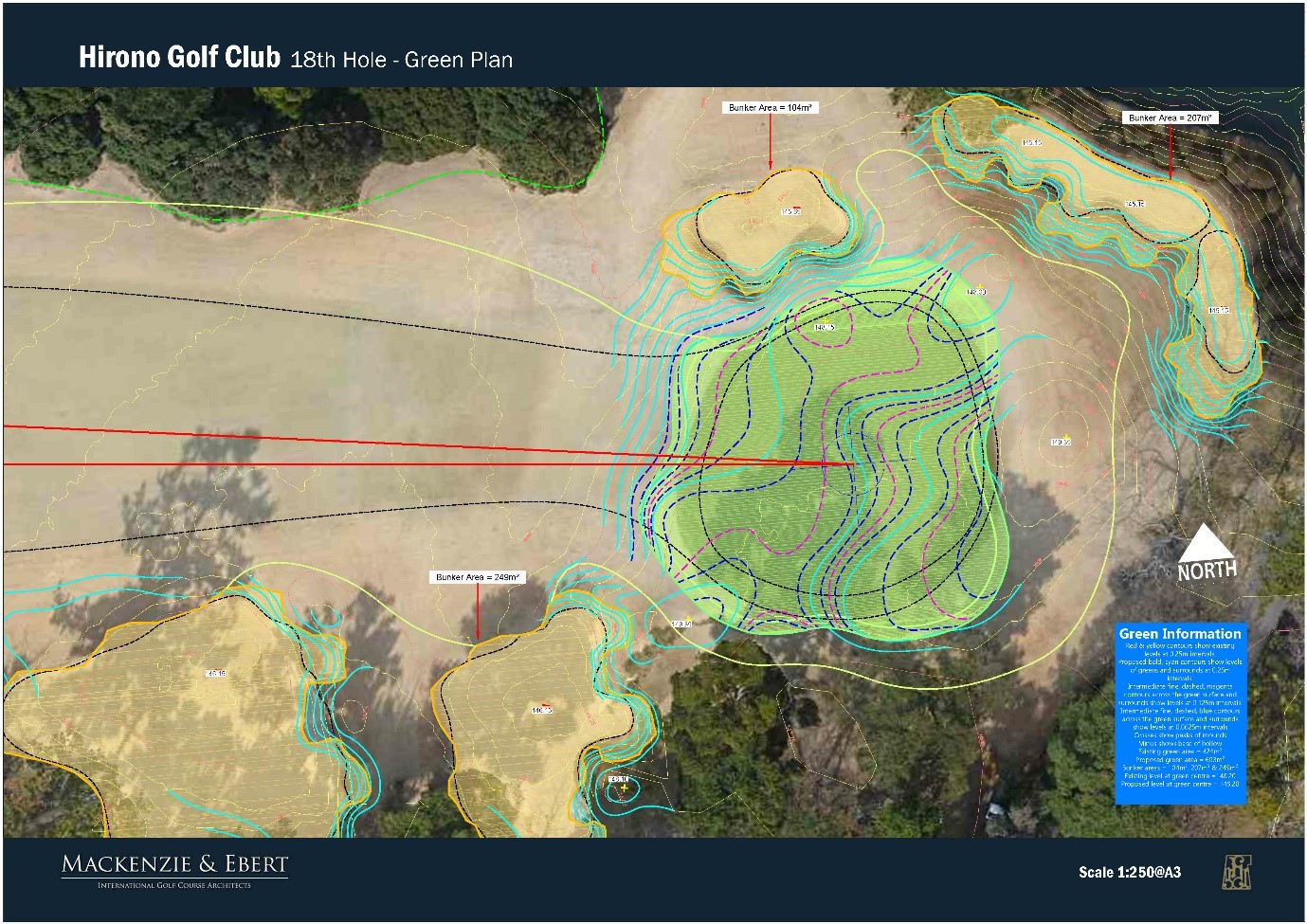

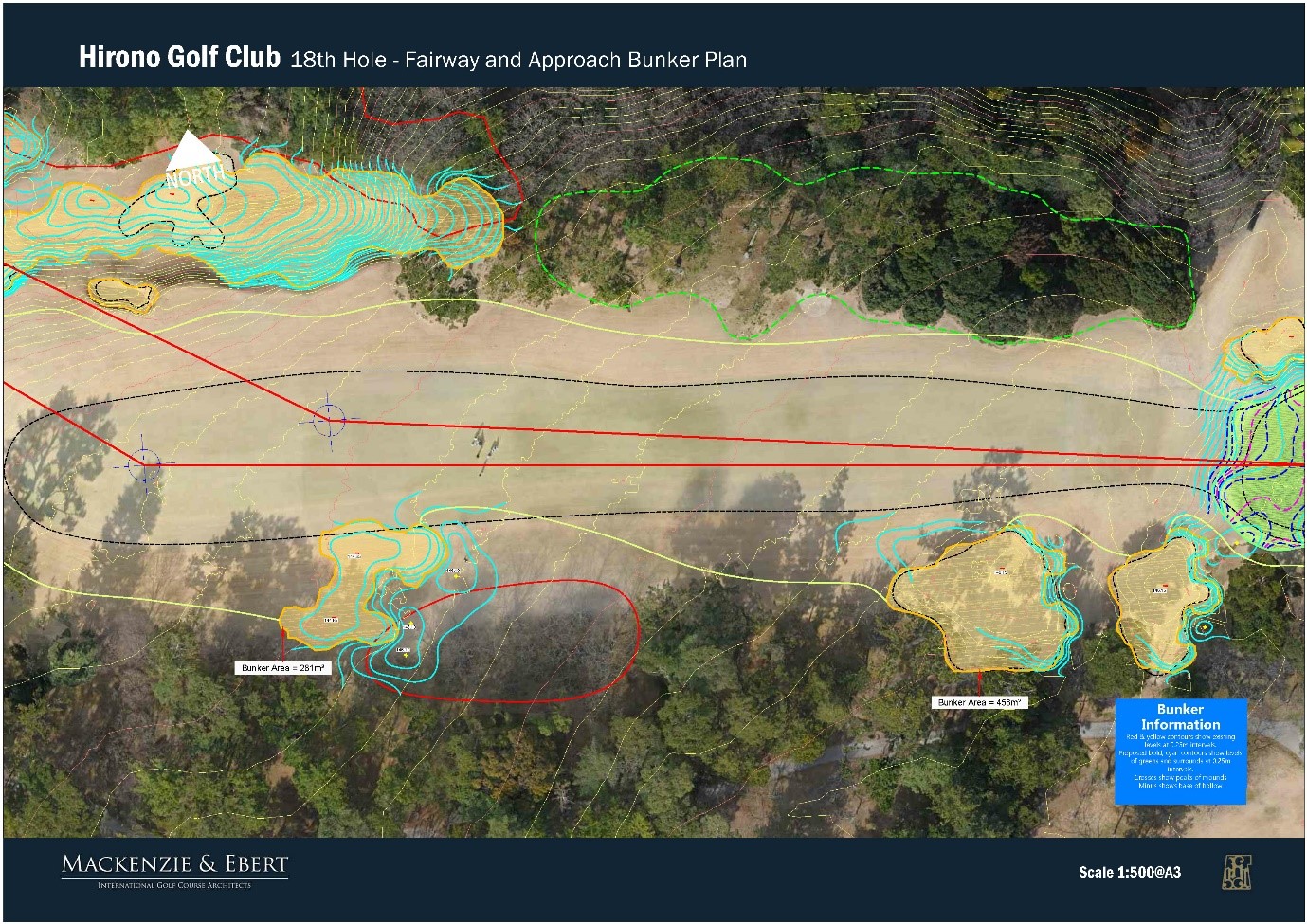

With the greens we felt confident, as our green plans are extremely detailed with levels being defined at 2.5 inches across the green surfaces and 10 inches for all areas of green surrounds and greenside bunkers. Most golfers may not realise that many golf course architects do not draw accurate plans and rely either on directing and approving designs on site, or by allowing their on-site personnel to effectively make the design during the shaping process. Our approach involves doing our thinking before construction starts on the ground and we have learnt to produce inspired designs on paper, which have worked for over the last 30 years. We have been told by contractors in many parts of the world that they rarely receive plans containing such detail.

In Japan, during the restoration project at Hirono carried out in 2019, only the most minor changes to the shaped greens were required during construction to create the absolute best end product, as the contractor and shaper had built the greens so accurately to the plans. Some of the contractors we work with have GPS equipment, which is able to control the machinery and allow perfectly accurate construction for all areas with our plans and levels loaded into the software.

However, approvals are still a vital part in achieving the best results and, occasionally, minor adjustment to the levels designed are required. For all areas, but particularly for the greens, we are using drone techniques to allow us to make approvals from the UK. Chris Huggett is our Civil Aviation Authority-qualified drone pilot and he had learnt mapping techniques for surveying courses to provide accurate levels of existing features or newly shaped features. Chris is able to send the project team the flight path routing for the grid pattern which the drone needs to follow to produce the survey information.

The local drone operator sends the information back and this is processed to produce an as-built green plan which can be compared with the green design to see how closely the levels agree with each other. The contours produced also give us an excellent impression of the all-important green surrounds and approaches. The drone can be used again to make a final check of levels before final approval of the green is given and seeding can commence. This process is followed for the green base shaping and the finished rootzone preparation to ensure the closest control over the green contours.

As described above, the drone survey analysis of the greens can be applied to these areas too and is quite valuable for the green surrounds shaping but an additional means of assessment was felt to be required. This comes in the form of 3D images of the shaped areas. We advised the client on the best 3D camera to purchase, with photographs and videos regularly being sent back to us in the UK.

We use a virtual reality headset to view the photographs and videos, which allows us to feel as though we are walking around and over greens, and in and out of bunkers, to give a complete and extremely realistic idea of the shapes being achieved. It really is like being at the course in person.

2D photos are also provided from tees and landing areas so that the golfers’ visibility of greens and, more importantly, bunkers can be assessed. Direction is given to the construction team via regular Zoom calls and we draw sand lines onto 2D photos of the bunkers to take the place of spraying out the bunker lines on the ground.

As the project progresses, these direction and approval processes should become ever more streamlined. The initial results have certainly been most encouraging.

The need to adopt these measures has been driven by the terrible situation affecting the whole world but we view the techniques as the future for our business. They will not replace the need to make visits and some projects may still require intensive on-site supervision. There are clients who value regular and frequent visits. However, these techniques will allow us to reduce them during the construction phases if that is considered appropriate. In some cases, it can also assist in the planning stages of the projects.

For instance, 13 visits were made to Japan in a 10-month period during 2019 to provide input at Hirono. That number might be reduced to seven or eight in future, although some clients appreciate the close attention to detail that regular on-site visits allows. However, reducing the number of visits will obviously allow travel and accommodation costs to be reduced for our clients and our carbon footprint will be lowered dramatically.

We conceived a few thoughts and ideas and had begun to consider how we might bring them into practice. Then Covid-19 came along, and we were locked down. How could we continue to serve our projects and maintain our standards? This was brought into focus with major projects getting started overseas in 2020.

Finally, to put matters into perspective, the original architects of some of the courses we work on like Old Tom Morris, Harry Colt, Charles Hugh Alison and Tom Simpson would not have been able to make too many visits to their projects when they first laid out their classic designs!

For further information please contact Martin Ebert & Tom Mackenzie by e mail at:- office@mackenzieandebert.com